Wilden

Since 1955, Wilden has been the market leader in air-operated double-diaphragm (AODD) pumps.

As a premier organization, Wilden has the infrastructure, knowledge base and intellectual capital to exceed customer expectations worldwide. Wilden is deeply committed to the pursuit of excellence, customer satisfaction, research and development, and market knowledge.

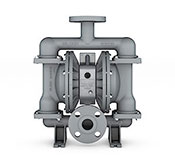

Bolted Metal Wilden® Advanced™ Air-Operated Double-Diaphragm (AODD) Pumps

Wilden®'s revolutionary Advanced™ Air-Operated Double-Diaphragm (AODD) bolted metal pumps were specifically engineered for maximum performance and efficiency in a variety of applications. Their bolted configuration ensures total product containment while the optimized liquid path reduces internal friction to maximize output and efficiency.

Wilden®'s revolutionary Advanced™ Air-Operated Double-Diaphragm (AODD) bolted metal pumps were specifically engineered for maximum performance and efficiency in a variety of applications. Their bolted configuration ensures total product containment while the optimized liquid path reduces internal friction to maximize output and efficiency.

A variety of elastomer options, including Teflon® PTFE, are available to meet abrasion, temperature and chemical-compatibility requirements. The Advanced™ Series metal pumps are offered in die-cast aluminum, stainless steel and alloy C. A variety of options such as ANSI and DIN flanges, NPT/BSPT threads, and specialized air distribution systems (ADS) are available to meet specific application requirements.

Bolted Plastic Wilden Advanced™Air-Operated Double-Diaphragm (AODD) Pumps

Wilden®'s revolutionary Advanced™ Series of Air-Operated Double-Diaphragm (AODD) bolted plastic pumps were specifically engineered for maximum performance and efficiency in a variety of applications. In choosing a plastic pump over a metal pump, price, chemical compatibility and mobility come into play. Some pumping applications require a pump that is mobile and available in multiple locations. The Wilden Advanced Series AODD plastic pump is lighter compared to metal pumps and is easier to transport. When chemical compatibility is critical, plastic AODD pumps provide an outstanding option over metal pumps that are incompatible with certain chemicals.

Wilden®'s revolutionary Advanced™ Series of Air-Operated Double-Diaphragm (AODD) bolted plastic pumps were specifically engineered for maximum performance and efficiency in a variety of applications. In choosing a plastic pump over a metal pump, price, chemical compatibility and mobility come into play. Some pumping applications require a pump that is mobile and available in multiple locations. The Wilden Advanced Series AODD plastic pump is lighter compared to metal pumps and is easier to transport. When chemical compatibility is critical, plastic AODD pumps provide an outstanding option over metal pumps that are incompatible with certain chemicals.

The bolted configuration ensures total product containment while the optimized liquid path reduces internal friction to maximize output and efficiency. A variety of elastomer options, including Teflon® PTFE, are available to meet abrasion, temperature and chemical-compatibility requirements. The Advanced™ Series plastic pumps are offered in polypropylene, PVDF and Teflon® PFA. A variety of options, such as ANSI and DIN flanges, and specialized air distribution systems (ADS) are available to meet specific application requirements.

Clamped Metal Wilden® Original™ Air-Operated Double-Diaphragm (AODD) Pumps

Wilden®'s legendary clamped Original™ metal Air-Operated Double-Diaphragm (AODD) pumps are perfect for demanding utilitarian applications that require a robust design and long-term dependability. The clamped configuration is the classic design that evolved from 1955 with the invention of Jim Wilden's first AODD pump now known as the Original™ Series.

Wilden®'s legendary clamped Original™ metal Air-Operated Double-Diaphragm (AODD) pumps are perfect for demanding utilitarian applications that require a robust design and long-term dependability. The clamped configuration is the classic design that evolved from 1955 with the invention of Jim Wilden's first AODD pump now known as the Original™ Series.

Wilden air pumps ensure reliability without sacrificing ease of maintenance. The clamp bands come off quickly and easily for replacement of diaphragms and cleaning. The lower downtime translates directly into your increased productivity and contributes to your profitability. Wilden's metal pump line lends itself to various processes and waste-handling applications. Wilden also offers a multitude of elastomer options, including Teflon® PTFE, to meet abrasion, temperature and chemical-compatibility requirements.

Clamped Plastic Wilden® Original™ Air-Operated Double-Diaphragm (AODD) Pumps

Wilden®'s legendary Original™ clamped plastic Air-Operated Double-Diaphragm (AODD) pumps are perfect for demanding utilitarian applications that require a robust design and long-term dependability. The clamped configuration ensures reliability without sacrificing ease of maintenance. The clamp bands are easily removed for replacement of diaphragms and easy cleaning.

Wilden®'s legendary Original™ clamped plastic Air-Operated Double-Diaphragm (AODD) pumps are perfect for demanding utilitarian applications that require a robust design and long-term dependability. The clamped configuration ensures reliability without sacrificing ease of maintenance. The clamp bands are easily removed for replacement of diaphragms and easy cleaning.

Wilden's plastic air pump line is ideally suited for various processes and waste-handling applications when chemical compatibility is a factor. The lighter weight plastic materials make Wilden Plastic Clamped pumps highly portable and less expensive than their metal counterparts. Wilden also offers a multitude of elastomer options, including Teflon® PTFE, to meet abrasion, temperature and chemical-compatibility requirements and specialized air distribution systems (ADS) are available to meet specific application requirements.

High Pressure Wilden® Air-Operated Double-Diaphragm (AODD) Pumps

The Wilden® High Pressure Series of Air-Operated Double-Diaphragm (AODD) pumps are reliably effective in transfering viscous, solid-laden slurries at high discharge pressures. Wilden’s premier simplex and duplex diaphragm and piston-pump technologies powerfully deliver pressures up to 20.7 bar (300 psig) making them perfect for a wide variety of high-pressure duties, including filtration, chemical-sludge transfer and general industrial applications.

The Wilden® High Pressure Series of Air-Operated Double-Diaphragm (AODD) pumps are reliably effective in transfering viscous, solid-laden slurries at high discharge pressures. Wilden’s premier simplex and duplex diaphragm and piston-pump technologies powerfully deliver pressures up to 20.7 bar (300 psig) making them perfect for a wide variety of high-pressure duties, including filtration, chemical-sludge transfer and general industrial applications.

Without the need for costly external boosters or amplifiers for most applications, Wilden high-pressure pumps provide maximum performance for the dollar. And with their bolted construction, these pumps offer maximum product containment.

Solids and Slurry Handling Wilden® Stallion™ and Brahma™ Air-Operated Double-Diaphragm (AODD) Pumps

The legendary Wilden® Stallion® and Brahma™ Air-Operated Double-Diaphragm (AODD) Pumps transfer solid-laden slurries safely and effectively. Large internal clearance and flow-through design result in large-solids passage capacity and prevent the pump from clogging.

The legendary Wilden® Stallion® and Brahma™ Air-Operated Double-Diaphragm (AODD) Pumps transfer solid-laden slurries safely and effectively. Large internal clearance and flow-through design result in large-solids passage capacity and prevent the pump from clogging.

Stallion technology incorporates an altered ball/seat check-valve assembly that maximizes part life, increases suction lift and optimizes flow rates. Its polyurethane screen base at the inlet gives added durability. Ready for the toughest utilitarian applications, such as mining, that require a robust design, the Stallion series provides simple installation and easy serviceability.

The Brahma utilizes a unique top inlet, bottom discharge orientation and flap valves to allow passage of large-size solids and avoid damage from product entrapment and settling of solids in intermittent-duty applications. It features bolted construction for superior containment and the ability to pass certain solids up to 76 mm (3″), depending on pump size.

Wilden pumps have the largest material and elastomer offerings in the industry to meet abrasion, temperature and chemical-compatibility challenges. A variety of connection options and specialized air distribution systems (ADS) are also available for your specific application needs.

For more information, please visit the Wilden website.